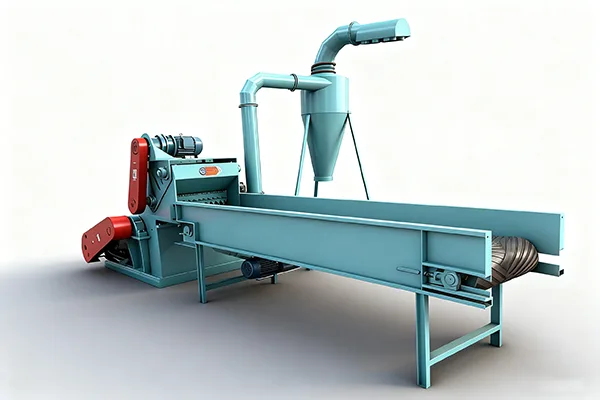

(diesel)Disc Wood Crusher

The diesel-powered mobile disc wood crusher is a wood processing machine equipped with a diesel engine and a mobile chassis. Requiring no external power source, this model excels in remote operations due to its exceptional mobility and field capability, making it particularly suitable for mobile applications in locations with limited electrical access, such as forestry sites and mountainous areas.

0-500MM

Feed size(Log size)

15-440HP

power

1-12T/H

Production capacity

Products Advantages

The diesel-powered mobile disc wood crusher boasts exceptional mobility and environmental adaptability. Equipped with a high-power diesel engine, this unit operates autonomously at various outdoor sites without requiring external power sources, making it particularly suitable for wood chipping needs in areas with limited electrical infrastructure, such as forestry operations and mountainous regions. Its heavy-duty chassis and travel system enable rapid relocation, effectively reducing raw material transportation costs and significantly enhancing the comprehensive utilization rate of wood resources.

diesel-powered mobile disc wood crusher

The diesel-powered mobile disc wood crusher uses a high-output engine to crush logs, branches, and timber. Its mobile design works across forestry sites and rugged terrain, ideal for logging, landscaping, and biomass fuel prep, cutting costs and boosting efficiency.

Disc Wood Crusher Production Capacity

Different models of disc wood crusher offer varying production capacities. Manto Machinery provides multiple capacity specifications: 0.8-1 t/h, 1.5 t/h, 2 t/h, 2.5 t/h, 3-4 t/h, 4-5 t/h, 6 t/h, 8-10 t/h, and 12 t/h. These options meet diverse production capacity requirements.

Disc-Type Wood Crusher Applicable Materials

The diesel-powered mobile disc wood crusher is suitable for processing various types of wood materials harvested and collected on-site. Applicable materials include: forestry residues such as logs, branches, and stumps generated from mountain forest harvesting; landscaping waste such as tree trunks and branches produced from garden pruning. This equipment can shred these materials into uniform wood chips.

Advantages of Disc Wood Chippers

The diesel-powered mobile disc wood crusher combines mobility, adaptability, and high output. With a diesel engine and mobile chassis, it works anywhere without external power. It handles logs, branches, and stumps up to 50 cm on-site, cutting transport costs. Alloy blades ensure 1–12 t/h capacity, producing uniform chips ideal for engineered wood and biomass fuel, maximizing resource value.

Working Principle

The working principle of the diesel-powered mobile disc wood crusher is as follows: The diesel engine provides power, driving the disc equipped with flying knives to rotate at high speed through the transmission system. Wood to be processed is fed through the inlet and encounters the rotating flying knives, where it is forcefully cut and crushed. The resulting wood chips are propelled through the screen and discharged from the outlet by the airflow generated by the rotating disc. The entire process requires no external power source, enabling autonomous mobile operation.

Model And Technical Parameter

| Model | power | Inlet size | Maximum feed size | Output Size | production capacity |

|---|---|---|---|---|---|

| Model 420 | 15HP | 150*160 mm | 130 mm | 1-20mm | 0.8-1 t/h |

| Model 500 | 32HP | 170*180 mm | 150 mm | 1-20mm | 1.5 t/h |

| Model 600 | 4100/60HP | 190*200 mm | 190 mm | 1-20mm | 2 t/h |

| Model 700 | 4102/102HP | 200*210 mm | 200 mm | 1-20mm | 2.5 t/h |

| Model 900 | 6105/155HP | 280*280 mm | 280 mm | 1-20mm | 3-4 t/h |

| Model 1000 | 6105/155HP | 280*280 mm | 280 mm | 1-20mm | 4-5 t/h |

| Model 1200 | 6108/220HP | 380*380 mm | 380 mm | 1-20mm | 6 t/h |

| Model 1500 | 6126/380HP | 440*460 mm | 440 mm | 1-20mm | 8-10 t/h |

| Model 1800 | 6126/440HP | 500*500 mm | 500 mm | 1-20mm | 12 t/h |

Note: The parameters in the table are for reference only. Products are subject to updates and changes. For the latest information, please contact us.

Related Products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.