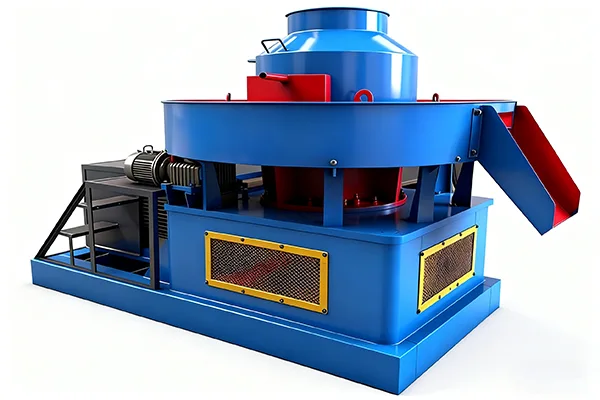

(Flat mold)Biomass pellet machine

Compact and cost-effective, this machine efficiently compresses biomass materials like sawdust and straw into solid pellets using a vertical flat die and roller system. Ideal for small-scale production, it offers easy operation and maintenance while delivering reliable performance for fuel and feed pellet applications.

0-5MM

Feed size

15-55KW

power

0.1-1T/H

Production capacity

Products Advantages

This compact unit utilizes a flat die head and rotating rollers to efficiently process biomass feedstock into solid pellets. Featuring simple operation, low investment costs, and adaptability to diverse materials, it is particularly suited for small-to-medium scale production, making it an ideal choice for farms, workshops, or small factories.

Flat Die Biomass Pellet Machine

This rugged machine is designed for small to medium-scale production, featuring a vertical flat die head and roller compaction system that efficiently compresses biomass materials (sawdust, straw, etc.) into high-quality solid pellets. Its user-friendly operation, low maintenance costs, and adaptability to various feedstocks make it an ideal solution for on-site pelletizing in farms, workshops, and small factories.

Flat Die Biomass Pellet Machine Production Capacity

Different models of biomass pellet machines offer multiple production capacity options. Manto Machinery provides the following single-unit capacity specifications: 0.1-0.2 tons per hour, 0.2-0.3 tons per hour, 0.3-0.4 tons per hour, 0.4-0.6 tons per hour, 0.6-0.8 tons per hour, and 0.7-1 ton per hour. Production lines can be customized according to specific output requirements.

Flat Die Biomass Pellet Machine Suitable Raw Materials

This equipment efficiently processes various biomass feedstocks, including wood chips, crop straw, forage, rice husks, and other agricultural residues. Feedstock particle size must be less than 6 millimeters, with moisture content below 18%. Its exceptional adaptability enables handling diverse material properties, making it particularly suitable for small-to-medium-scale production of fuel pellets, animal feed, and other products using readily available local resources.

Advantages of Flat Die Biomass Pellet Machines

This machine stands out for its compact vertical design, simple operation, and low maintenance requirements. Offering greater flexibility in handling various biomass materials with lower investment and energy consumption, it delivers reliable performance for small to medium-scale pellet production. The robust construction ensures long service life, making it an ideal cost-effective solution for farms and workshops.

Working Principle

This machine operates with a vertical design where the press rollers rotate over a stationary flat die. Biomass material is fed from above, compressed into the die holes by the rollers, and extruded into dense pellets below. The process generates sufficient heat to activate natural binders in the material, forming solid pellets without additives, which are then cut to uniform length by an adjustable blade.

Model And Technical Parameter

| Model | power (kw) | capacity (kg/h) |

|---|---|---|

| 250 | 15kw | 100-200 |

| 300 | 22kw | 200-300 |

| 350 | 30kw | 300-400 |

| 400 | 37kw | 400-600 |

| 500 | 55kw | 700-1000 |

Note: The parameters in the table are for reference only. Products are subject to updates and changes. For the latest information, please contact us.

Related Products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.