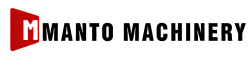

Automatic feed wood crusher

The forced-feed wood crusher uses hydraulic rollers to automatically grip and pull in wood materials, ensuring efficient, continuous processing with enhanced operational safety.

0-1300MM

Feed size(Board width)

22-90KW

power

0.5-4T/H

Production capacity

Products Advantages

The forced-feed wood Crusher drives a feed roller that automatically grips and smoothly conveys branches and logs at a controlled speed. This innovative feeding mechanism ensures stable, high-efficiency bulk processing while significantly enhancing operational safety by minimizing direct operator contact with the cutting system. The equipment effortlessly handles wood of varying diameters, substantially reducing manual labor intensity. It is particularly suited for commercial forestry and landscaping projects requiring efficient continuous operation.

Forced-Feed Wood Crusher

The forced-feed wood crusher employs feed rollers to automatically grasp timber and pull it in at a steady pace, ensuring efficient continuous operation while enhancing safety by keeping operators away from the cutting mechanism. This equipment is suitable for commercial use and effortlessly handles timber of various sizes.

Forced-Feed Wood Crusher Production Capacity

Different models of forced-feed wood crusher offer varying processing capacities. Manto Machinery provides multiple capacity specifications: 0.5-1.5 tons per hour, 1.5-2 tons per hour, 2-2.5 tons per hour, 2.5-3 tons per hour, and 3.5-4 tons per hour to meet your specific production requirements.

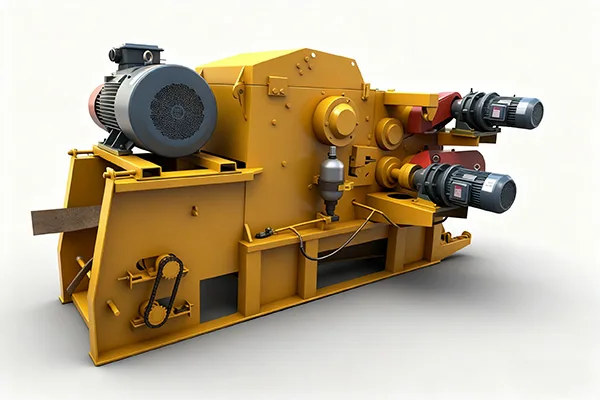

Forced-Feed Wood Crusher Suitable Materials

This forced-feed wood crusher efficiently processes various wood materials, including branches, logs (within specified diameter range), shrubs, coconut shells, sawmill offcuts, and pallets. It reduces them into uniform wood chips suitable for mulch, biomass fuel, or other recycling applications.

Advantages of the Forced-Feed Wood Crusher

The core advantage of the forced-feed wood crusher lies in its automatic feeding system, which ensures sustained high-output processing capacity and greater material compatibility. This significantly reduces labor requirements while enhancing safety by minimizing operator exposure. Consequently, the equipment delivers outstanding efficiency in commercial wood recycling and landscaping operations.

Working Principle

The forced-feed wood Crusher operates through an automated process where hydraulic-powered rollers first grip and steadily pull branches into the machine. This consistent feed mechanism directs the wood toward a high-speed cutting disk equipped with hardened steel blades. The rotating disk efficiently shreds the material into uniform wood chips, which are then discharged through an adjustable output chute. This controlled feeding system ensures optimal processing efficiency while maintaining operational safety.

Model And Technical Parameter

| Model | power | Maximum feed size | Output Size | production capacity |

|---|---|---|---|---|

| Model 500 | 22kw | 500*150 mm | 1-20mm | 0.5-1.5 t/h |

| Model 600 | 30kw | 600*150 mm | 1-20mm | 1.5-2 t/h |

| Model 800 | 45kw | 800*150 mm | 1-20mm | 1.5-2.5t/h |

| Model 1000 | 75kw | 1000*150 mm | 1-20mm | 2-2.5t/h |

| Model 1300 | 90kw | 1300*150 mm | 1-20mm | 3.5-4t/h |

Note: The parameters in the table are for reference only. Products are subject to updates and changes. For the latest information, please contact us.

Related Products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.