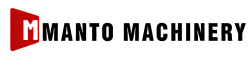

Biomass Briquette Machine

This equipment utilizes a ring-shaped mold and pressure rollers to compress biomass waste into high-density blocks. It converts raw materials such as sawdust and straw into clean-burning biofuel suitable for heating and industrial applications.

0-10MM

Feed size

55-110KW

power

1-3T/H

Production capacity

IProducts Advantages

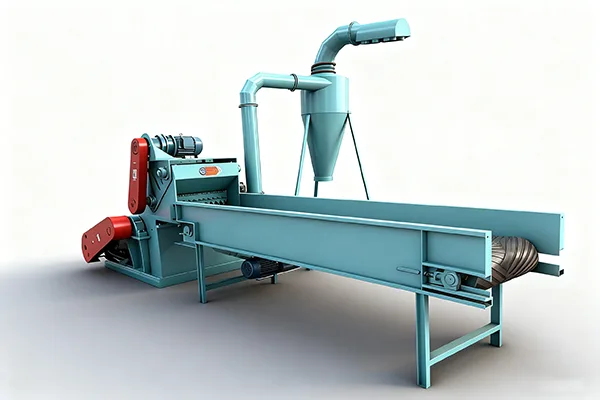

The Biomass Briquette Machine utilizes a rotating ring die and roller compression mechanism to compress biomass waste into high-density coal briquettes. It features high output, uniform briquette quality, and energy-efficient operation, making it suitable for large-scale production of solid biofuels. Raw materials include sawdust, crop residues, and various other types.

Biomass Briquette Machine

The Biomass Briquette Machine utilizes a ring die and roller compression system to convert various biomass materials into high-density coal-like briquettes. It is suitable for processing wood waste, agricultural residues, and other biomass into clean-burning solid biofuels, meeting heating and industrial application needs. While delivering reliable performance, it requires only minimal maintenance.

Biomass Briquette Machine Capacity

Different models of Biomass Briquette Machine offer multiple production capacity options. Manto Machinery provides the following single-unit capacity specifications: 1-1.5 tons per hour and 2-3 tons per hour. Production lines can be customized according to specific output requirements.

Suitable Raw Materials for Biomass Briquette Machine

Suitable for processing wood chips, sawdust, crop straw, rice husks, and other agricultural and forestry residues, with particle sizes less than 10 millimeters and moisture content below 20%. It efficiently converts various biomass waste into high-density solid biofuel without requiring the addition of binders.

Advantages of Biomass Briquette Machine

The biomass briquetting machine features high production efficiency, excellent forming density, and low energy consumption. Its durable ring die ensures a long service life and stable operation, supporting large-scale continuous biomass briquette production while significantly reducing maintenance costs.

Working Principle

This equipment employs a horizontally rotating ring die and internal compression rollers to compress biomass materials. After being fed into the chamber, the raw material is forced through the forming holes of the ring die under high pressure by the compression rollers. Solid fuel rods are formed without the need for additives. The compacted fuel rods undergo continuous extrusion and are cut into uniform lengths by adjustable blades, ultimately yielding high-density, well-shaped products perfectly suited for the biofuel sector.

Model And Technical Parameter

| Model | 600 | 900 |

|---|---|---|

| power (kw) | 55kw | 110kw |

| Output Size (mm) | 20-30 | 20-30 |

| capacity (t/h) | 1-1.5 | 2-3 |

Note: The parameters in the table are for reference only. Products are subject to updates and changes. For the latest information, please contact us.

IRelated Products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.