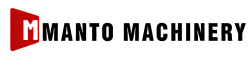

Comprehensive wood crusher

The Comprehensive Wood Crusher is a primary coarse crushing equipment, serving as the main machine in the first stage of wood processing.

0-400MM

Feed size(Log size)

37-160KW

power

3-40T/H

Production capacity

Product Advantages

The Comprehensive Wood Crusher is a coarse crushing machine, designed for primary processing of logs, branches, and waste wood in recycling lines.Can crush these raw materials into manageable sizes.

Comprehensive Wood Crusher

As a key coarse crushing unit, the Comprehensive wood crusher ensures reliable first-stage processing of wood materials in industrial recycling systems.

Comprehensive wood crusher capacity range

Different models of Comprehensive Wood Crusher have different production capacities. Manto Machinery offers a range of capacities of 3-5t/h, 5-8t/h, 8-10t/h, 15-20t/h, and 30-40t/h.These options meet diverse production capacity requirements.

Suitable materials for Comprehensive Crusher

Suitable for wood fiber materials such as logs, branches, planks, straw, building formwork, wooden pallets, discarded furniture, bamboo, coconut shells, etc. After crushing, they can be used in biomass fuel, composting, and edible fungus cultivation. It can also crush some thin iron sheets, plastics, etc.

Advantages of Comprehensive Wood Crusher

Manto machinery comprehensive wood crushers can crush a wide range of raw materials, support personalized customization, and are economical and practical. They are widely used in sawmills, forestry, and biomass fuel industries.

Working Principle

The Comprehensive Wood Crusher employs rotating blades working in tandem with stationary cutting tools to perform cutting, shearing, and shredding operations on raw materials such as logs, branches, bamboo, and pallets. Through a combined cutting and screening process, materials are processed into uniform sizes. Final particle size can be adjusted according to screen specifications, making it the primary crushing equipment for oversized timber. This machine can be powered by electric motors or diesel engines, ensuring efficient and stable operation. It serves as an ideal processing solution for sawmills, biomass plants, and the recycling industry.

Model and technical parameters

| Model | 600 | 800 | 1000 | 1300 | 1600 |

|---|---|---|---|---|---|

| power (kw) | 37kw | 55kw | 90kw | 110kw | 160kw |

| Feed opening width (mm) | 600 | 800 | 1000 | 1300 | 1600 |

| Maximum feed size (mm) | 200 | 250 | 280 | 350 | 400 |

| Feed conveyor dimensions | 4.5m | 4.5m | 5m | 5m | 5m |

| Discharge conveyor dimensions | 6m | 8m | 10m | 10m | 10m |

| Discharge size (mm) | 5-50 | 5-50 | 10-50 | 20-50 | 20-50 |

| capacity (t/h) | 3-5 | 5-8 | 8-10 | 15-20 | 30-40 |

Note: The parameters in the table are for reference only. Products are subject to updates and changes. For the latest information, please contact us.

The maximum feed size data refers to the diameter of the logs.

Related products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.