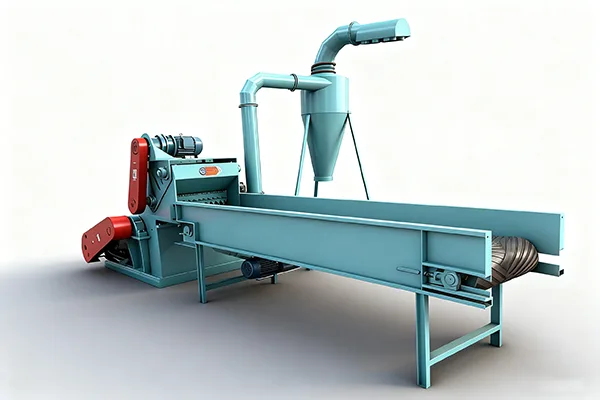

Disc-Type Wood Chipper

The Disc Chipper is a robust machine designed for high-volume production of uniform wood chips from logs and wood waste, ideal for pulp, paper, and biomass energy.

0-380MM

Feed size(Log size)

7.5-90KW

power

1-14T/H

Production capacity

Products Advantages

Disc chippers excel at high-volume production of uniform chips, crucial for pulp and biomass. Their robust, simple design ensures durability, low maintenance, and consistent output for industrial processing.

Disc-Type Wood Chipper

The disc wood chipper is specifically designed to process logs, branches, and wood waste into uniform wood chips. Its core component is a heavy-duty rotating disc equipped with hardened blades that shreds wood through a shearing action. Renowned for its robust construction and high production efficiency, this equipment delivers a consistent output of precisely sized wood chips. It is ideally suited for the pulp, paper, panel, and biomass energy industries, establishing itself as a fundamental piece of equipment in modern wood processing.

Disc-Type Wood Chipper Production Capacity

Different models of disc wood chippers offer varying production capacities. Manto machinery offers a variety of capacity options: 0.8-1 t/h, 2-3 t/h, 3-4 t/h, 7-8 t/h, 8-10 t/h, and 12-14 t/h. These options cater to diverse production needs.

Disc-Type Wood Chipper Applicable Materials

The disc wood chipper boasts versatile applications and can process a wide range of materials. It is particularly well-suited for handling whole logs, lumber boards, and wood blocks from various tree species. Additionally, it efficiently processes forest and sawmill residues such as branches, tree tops, and offcuts. This equipment is indispensable for paper mills, biomass power plants, and wood recycling centers.

Advantages of Disc-Type Wood Chippers

The disc wood chipper stands out for its exceptional efficiency and outstanding value for money. Its streamlined design ensures remarkable durability and minimal maintenance requirements, resulting in low operating costs. It consistently produces uniform, high-quality wood chips, which are crucial for achieving optimal yields in pulp and paper production as well as biomass energy generation. The perfect combination of reliability, output quality, and production efficiency makes it an excellent and cost-effective choice for intensive industrial processing applications.

Working Principle

The core component of the disc chipper is a high-speed rotating heavy-duty steel disc, with multiple alloy steel blades radially mounted on its surface. When the disc spins at high speed, logs or wood waste are fed into the machine through a hopper. The material is chipped into small wood pieces by the rotating disc equipped with blades. These uniform chips pass through slots in the disc and are ejected from the machine by centrifugal force, ready for collection and subsequent processing.

Model And Technical Parameter

| Model | power (kw) | Inlet size (mm) | Maximum feed size (mm) | Finished Size (mm) | capacity (t/h) |

|---|---|---|---|---|---|

| 420 | 7.5kw | 110*110 | 100 | 10-30 | 0.8-1 |

| 600 | 15kw | 180*180 | 170 | 10-30 | 2-3 |

| 800 | 30kw | 220*230 | 210 | 10-30 | 3-4 |

| 950 | 37kw | 250*260 | 240 | 10-30 | 7-8 |

| 1200 | 55kw | 320*330 | 300 | 10-30 | 8-10 |

| 1400 | 90kw | 400*410 | 380 | 10-30 | 12-14 |

Note: The parameters in the table are for reference only. Products are subject to updates and changes. For the latest information, please contact us.

IRelated Products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.