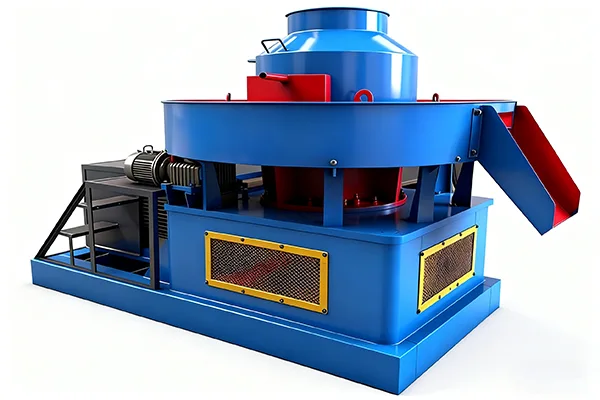

Disc Wood Crusher

The disc wood crusher is a crushing machine that uses a high-speed rotating blade disc to cut wood into standardized wood chips. It serves as a key piece of machinery in fields such as edible fungus cultivation, engineered wood products, and biomass energy.

0-500MM

Feed size(Log size)

7.5-132KW

power

1-12T/H

Production capacity

Products Advantages

The disc wood crusher is a specialized machine that shreds wood using high-speed rotating alloy blades. It processes logs, branches, lumber, and other timber into uniformly sized wood chips with consistent output and stable production capacity. As a core piece of equipment, it enables large-scale, comprehensive utilization of wood resources in industries such as papermaking, engineered wood manufacturing, biomass fuel preparation, and edible mushroom cultivation.

Disc Wood Crusher

The disc wood crusher stands as one of the core pieces of equipment in the wood processing industry. It primarily employs a high-speed rotating alloy steel disc to drive multiple sets of flying blades, efficiently cutting and shredding logs, branches, and various other types of wood. The finished product size can be flexibly adjusted by replacing screens with different aperture sizes. The disc wood chipper plays an irreplaceable and vital role in achieving the efficient comprehensive utilization and sustainable development of wood resources.

Disc Wood Crusher Production Capacity

Different models of disc wood crusher offer varying production capacities. Manto Machinery provides multiple capacity specifications: 0.8-1 t/h, 1.5 t/h, 2 t/h, 2.5 t/h, 3-4 t/h, 4-5 t/h, 6 t/h, 8-10 t/h, and 12 t/h. These options meet diverse production capacity requirements.

Disc-Type Wood Crusher Applicable Raw Materials

The disc wood crusher features broad material adaptability, efficiently processing various forestry and wood processing residues. Its primary suitable materials include: logs and small-diameter wood from all tree species, branches and twigs left over from forest harvesting; wood processing offcuts and slats; as well as green waste such as branches and tree trunks from urban landscaping pruning.

Advantages of the Disc Wood Crusher

The core advantage of the disc-type wood crusher lies in its ability to efficiently and precisely process various wood materials—including logs, branches, and scrap wood—transforming them into high-quality wood chips of uniform size and consistent specifications. This equipment employs a shear-type design combining cutting discs with flying knives to achieve high-output continuous operation. It not only demonstrates strong adaptability to diverse wood forms but also significantly enhances the comprehensive utilization rate of wood resources, providing reliable assurance for large-scale production.

Working Principle

The disc wood crusher is a core piece of equipment that uses a high-speed rotating disc to drive flying knives, cutting and shredding wood to produce uniformly sized wood chips. It feeds logs, branches, and scrap wood through the inlet, where the interaction between the flying knives and screen breaks the material into chips that meet specifications before discharging them. The machine primarily consists of a base frame, cutter disc, and flying knife drive system. Its key features include uniform and consistent output, high production efficiency, and strong adaptability. Consequently, it is widely used in paper manufacturing, engineered wood production, biomass energy, edible mushroom cultivation, and landscape waste processing. It serves as a critical piece of machinery for achieving efficient and comprehensive utilization of wood resources.

Model And Technical Parameter

| Model | power | Inlet size | Maximum feed size | Output Size | production capacity |

|---|---|---|---|---|---|

| Model 420 | 7.5kw | 150*160 mm | 130 mm | 1-20mm | 0.8-1 t/h |

| Model 500 | 18.5kw | 170*180 mm | 150 mm | 1-20mm | 1.5 t/h |

| Model 600 | 30kw | 190*200 mm | 190 mm | 1-20mm | 2 t/h |

| Model 700 | 37kw | 200*210 mm | 200 mm | 1-20mm | 2.5 t/h |

| Model 900 | 55kw | 280*280 mm | 280 mm | 1-20mm | 3-4 t/h |

| Model 1000 | 75kw | 280*280 mm | 280 mm | 1-20mm | 4-5 t/h |

| Model 1200 | 90kw | 380*380 mm | 380 mm | 1-20mm | 6 t/h |

| Model 1500 | 110kw | 440*460 mm | 440 mm | 1-20mm | 8-10 t/h |

| Model 1800 | 132kw | 500*500 mm | 500 mm | 1-20mm | 12 t/h |

Note: The parameters in the table are for reference only. Products are subject to updates and changes. For the latest information, please contact us.

Related Products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.