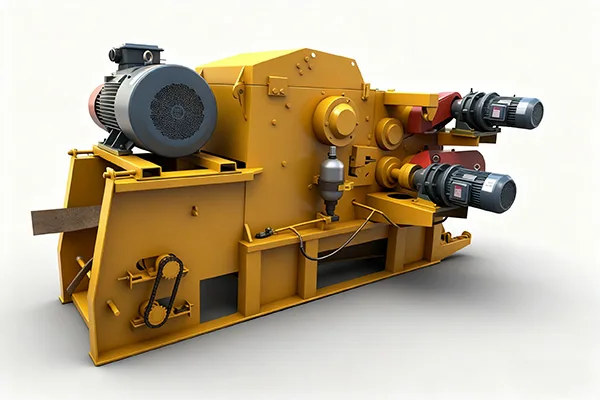

Drum-Type Wood Chipper

The drum wood chipper utilizes a heavy-duty rotating drum with mounted knives to process wood. It’s renowned for its high torque and ability to handle large-diameter logs, irregular shapes, and even whole trees with high efficiency.

0-300MM

Feed size(Log size)

55-110KW

power

5-20T/H

Production capacity

Products Advantages

The drum chipper excels at processing large irregular wood and entire trees, delivering high torque efficiency. Its robust design ensures outstanding durability and achieves lower energy consumption per ton, making it an ideal choice for high-output, demanding applications.

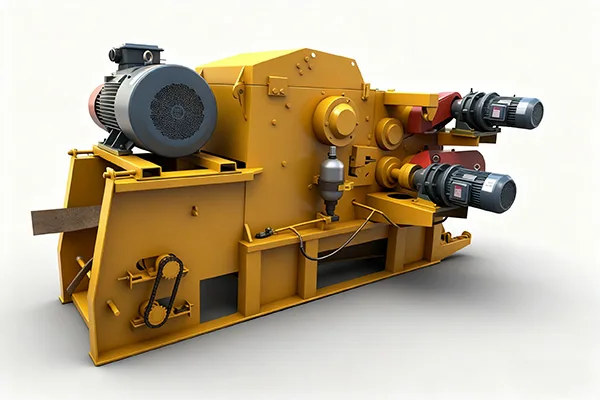

Drum-Type Wood Chipper

The drum wood chipper is a heavy-duty industrial machine designed specifically for processing mixed wood. Its core component is a rotating steel drum equipped with alloy steel blades, capable of shearing wood with immense torque. Renowned for its robust construction and capacity to process large-diameter materials, this machine excels at handling whole trees, logs, stumps, and irregular forest residues. This makes it an indispensable asset for large-scale forestry operations, sawmills, and biomass processing facilities, meeting the highest demands for throughput and durability.

Drum-Type Wood Chipper Production Capacity

Different models of drum wood chippers offer multiple production capacity options. Manto Machinery provides the following capacity specifications: 5-8 tons per hour and 15-20 tons per hour. These options can meet diverse production demands.

Drum-Type Wood Chipper Applicable Materials

The drum-type wood chipper is specifically designed to process complex wood materials, making it ideal for sawmill waste, small wood pieces, coconut shells, shrubs, large-diameter logs, and logging residues. Its wide feed opening efficiently handles irregularly shaped timber, stumps, and forest residues generated during land clearing operations. It is indispensable for forestry enterprises, sawmills, and the biomass energy industry.

Advantages of Drum-Type Wood Chippers

The core competitive advantage of the drum wood chipper lies in its efficient processing of large-diameter logs, whole trees, and irregular forest debris. Its high-torque, low-speed operating mode effectively reduces energy consumption. The robust and streamlined mechanical design enhances equipment durability while minimizing maintenance downtime. This seamless integration of power, material adaptability, and operational efficiency makes it the preferred choice for high-volume chipping in demanding applications such as large-scale forestry operations and sawmill residue processing.

Working Principle

The drum-type wood chipper operates by feeding timber into a rotating steel drum equipped with alloy steel blades. As the drum rotates, the blades seize the wood and press it against stationary counterblades and bottom blades for shearing. This powerful crushing action cuts the material into uniform wood chips, which are then discharged through the outlet chute via the combined action of the drum’s motion and airflow.

Model And Technical Parameter

| Model | 216 | 218 |

|---|---|---|

| power (mm) | 55kw | 110kw |

| Feed opening size (mm) | 500*230 | 680*300 |

| Maximum feed size (mm) | 230 | 300 |

| Finished wood chip size (mm) | 20-30 | 20-30 |

| capacity (t/h) | 5-8 | 15-20 |

Note: The parameters in the table are for reference only. Products are subject to updates and changes. For the latest information, please contact us.

Related Products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.