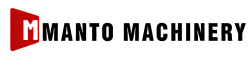

Ultrafine Wood Powder Grinder

Ideal for processing wood chips, sawdust, and biomass into fine powder (50-500 mesh). Features high efficiency, low energy consumption, and adjustable fineness.

0.8-2MM

Feed size

150KW

power

1-2T/H

Production capacity

Products Advantages

The ultrafine wood powder machine is designed to grind wood, bamboo, and other biomass materials into extremely fine powder, ideal for applications in incense making, wood-plastic composites, coatings, and high-grade biomass materials.

ultrafine wood powder machine

The ultrafine wood powder machine is a high-efficiency milling device specialized in producing fine and uniform wood powder from raw materials such as wood, bamboo, branches, and sawdust. It is widely used in industries like incense making, coatings, rubber, plastics, and biomass fuel, ensuring stable performance and consistent particle size.

ultrafine wood powder machine Capacity

Different models of wood powder machines offer multiple production capacity options. Manto Machinery provides the following capacity specifications: 1-2 tons per hour. Output fineness ranges from 50 to 500 mesh, with output varying based on the required fineness. Final output depends on the expected particle size of the finished product.

ultrafine wood powder machine Applicable Raw Materials

The ultrafine wood powder machine is suitable for processing wood chips, sawdust, bamboo, coconut shells, tree bark, and other biomass materials into fine powder.

Advantages of ultrafine wood powder machine

The ultrafine wood powder machine features high precision grinding, producing exceptionally fine and uniform powder, ideal for applications requiring superior smoothness and consistency.

Working Principle

This mill utilizes high-speed rotation to generate intense air flow and powerful mechanical impact; within its grinding chamber, materials are violently sheared, collided, and frictionally pulverized between the rotating disc/beaters and the stationary liner, and the resulting fine powder is then automatically separated and collected by an integrated air classifier to achieve a uniformly fine product.

Model And Technical Parameter

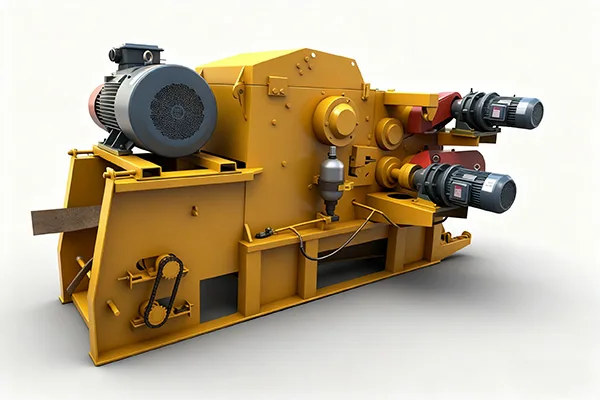

Related Products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.