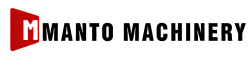

Water drop hammer mill

This shredder features a unique teardrop-shaped chamber design that creates optimal airflow for finer wood pulverization. It transforms biomass materials such as wood chips, branches, and bark into uniform particles with low noise and high output, making it an ideal choice for fuel and material pretreatment.

0-100MM

Feed size(Board width)

55-160KW

power

2-12T/H

Production capacity

Products Advantages

The Water drop hammer mill features a unique teardrop-shaped grinding chamber design that generates turbulent airflow for faster, more efficient grinding. It processes wood chips, branches, and other biomass materials into uniformly sized particles ranging from 1 to 5 millimeters, characterized by low noise, high output, and minimal dust emissions. It is particularly suitable for biofuel production and composite material preparation.

Water drop hammer mill

The Water drop hammer mill features a unique teardrop-shaped grinding chamber design that achieves exceptional grinding efficiency through optimized airflow. It rapidly pulverizes wood chips, branches, and other biomass materials into uniform particles measuring 1-5 millimeters. Characterized by low energy consumption, minimal dust generation, and stable operation, it perfectly meets the requirements for biofuel production and material pretreatment.

Water drop hammer mill Capacity

Different models of integrated wood chippers offer varying production capacities. Manto Machinery provides multiple capacity specifications, including 2-3 tons per hour, 3-5 tons per hour, 5-8 tons per hour, 6-10 tons per hour, and 10-12 tons per hour, to meet diverse production demands.

Suitable Materials for Water drop hammer mill

Suitable for processing various wood waste, branches, bamboo, crop straw, and other biomass materials. It efficiently handles raw materials with moisture content up to 25%, producing uniform pellets suitable for biofuel, composting, and other applications.

Advantages of Water drop hammer mill

Boasts unique chamber design for superior crushing efficiency and lower energy consumption. Delivers uniform particle size, minimal dust, and quiet operation. Its robust construction ensures durability and easy maintenance, making it ideal for efficient biomass processing.

Working Principle

This crusher employs a unique teardrop-shaped chamber structure that generates self-circulating airflow during operation. High-speed rotating hammers impact and shear materials against serrated liners, while the optimized chamber design enhances material collision efficiency and minimizes energy loss. Turbulent airflow ensures efficient screening and discharge of crushed particles, yielding finer, more uniform-sized finished products with higher production efficiency.

Model And Technical Parameter

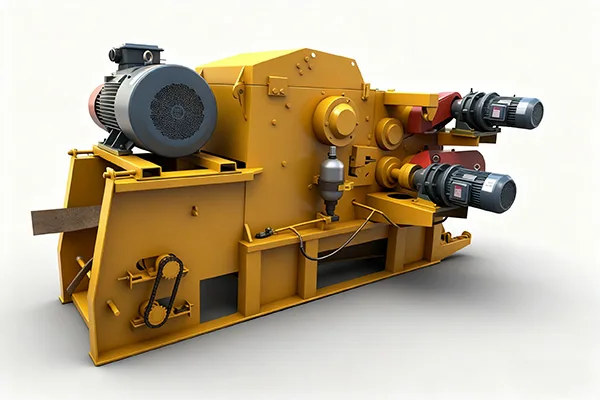

Related Products

Enquiry

If you wish to submit a formal inquiry, you may do so by completing the form below.

Note: Fields marked with * are required.