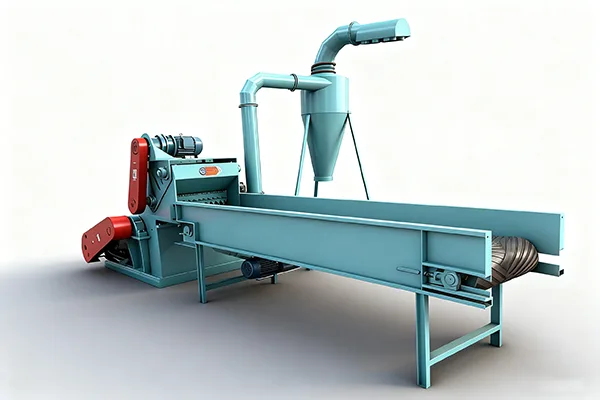

When customers search for a wood crusher for charcoal production, they are usually looking for a reliable machine that can process raw wood materials into uniform sizes suitable for carbonization. This type of equipment plays a critical role in the charcoal manufacturing process by improving efficiency, reducing labor costs, and ensuring consistent charcoal quality.

A wood crusher for charcoal production is designed to crush logs, branches, wood offcuts, and forestry waste into small chips or sawdust. These materials are ideal feedstock for charcoal kilns, carbonization furnaces, and charcoal briquette machines. By pre-crushing raw materials, manufacturers can achieve faster carbonization, higher output, and more stable combustion performance.

From a buyer’s perspective, common search concerns include crushing capacity, power options, and material compatibility. Modern wood crushers are available in electric, diesel, and PTO-driven models, making them suitable for factories, rural areas, and mobile charcoal production lines. Heavy-duty blades and reinforced hammer systems allow the crusher to handle hardwood, softwood, bamboo, and even pallet waste efficiently.

Another key reason customers search for this equipment is cost control. Using a wood crusher for charcoal production helps maximize raw material utilization by converting waste wood into valuable charcoal feedstock. This not only lowers production costs but also supports sustainable and eco-friendly charcoal manufacturing.

For businesses entering the charcoal industry or expanding existing operations, choosing the right wood crusher ensures stable raw material supply and consistent product quality. Whether for BBQ charcoal, industrial carbon, or charcoal briquettes, a well-matched wood crushing solution directly impacts profitability and long-term success.